Source: Gold-foil, Science Learning

Ductility is a solid material's ability to change shape under tensile stress. Tensile stress is the stress on an object that results from pulling or stretching (think of the word “tension”). This property is often characterized by the ability of the material to be stretched into a wire. Malleability is the material's capacity to change shapes under compressive stress. Malleability is often characterized by the capacity of the material to form a thin sheet when it is hammered or rolled.

The image below is a sheet of gold, foil. The element, gold can be pressed or hammered into thin sheets due to its malleability.

Source: Gold-foil, Science Learning

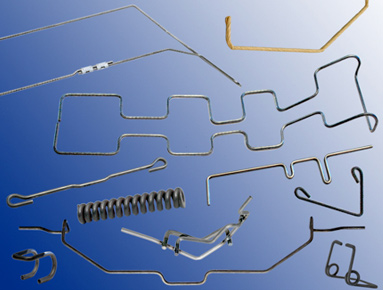

This image shows how metals can be drawn, or formed, into wires of different shapes.

Source: Wire Forming, Blue Grass Metals

The animation below shows how the delocalized electrons of the metallic bond in the 'sea' of electrons allow the metal atoms to roll over each other when a stress is applied. Because of this ability, the metal can be hammered into sheets (malleable) or pulled into wires (ductility), depending on the type of stress.

![]() Click on the animation to see how the delocalized electrons of the metal atoms roll over each other when stress is applied.

Click on the animation to see how the delocalized electrons of the metal atoms roll over each other when stress is applied.